How is the aircraft maintained on a daily basis?

- Share

- publisher

- JEET VIDEOSCOPE

- Issue Time

- Jul 11,2022

Summary

Shenzhen JEET Company has a highly educated R&D team with more than ten years of experience in endoscopes, specializing in R&D and production of industrial endoscopes, 3D measurement videoscopes, automotive videoscopes, police videoscopes, hole detectors, various videoscopes products such as borescope can provide targeted solutions for our customers. If you have related needs, welcome to communicate with us.

How is the aircraft maintained on a daily basis?

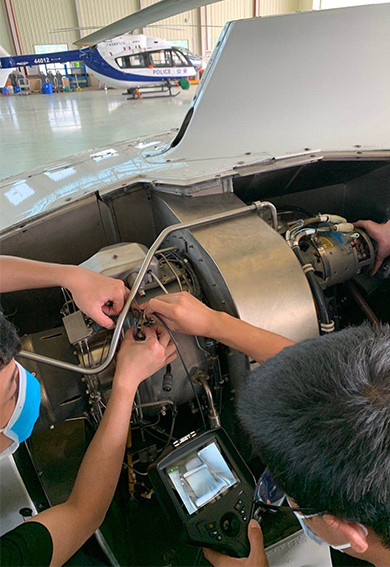

The safe flight of aircraft cannot be separated from daily careful maintenance. Due to wear, looseness, fracture or corrosion of aircraft engines and airborne equipment, the aircraft may lose some or all of its original functions (that is, reduce or lose the inherent reliability of the aircraft, directly affecting flight safety). However, due to the extremely complex structure of the aircraft engine, the routine maintenance and inspection cannot always check the problem through disassembly. In order to avoid the high maintenance cost caused by disassembly, it is necessary to complete the regular inspection by commonly known as "borescope", that is, endoscope, which is also one of the most important means in the daily maintenance and routine inspection of the aircraft engine. Therefore, every time the aircraft takes off, it needs to be carefully checked and tested to ensure whether its flight is really safe. Through the maintenance and repair of high-definition visual endoscope of JEET Technology, the inherent reliability of the aircraft can be restored to ensure flight safety and reduce costs.

What is the hole detection/engine borescope/endoskop kamera ?

The work of borescope detection/endoscopy is is like that of a doctor, who carefully, clearly and comprehensively inspects the "heart" - engine of a helicopter. Through the hole detection/engine borescope/endoskop kamera, the hidden dangers inside the engine can be found in advance, which provides an important reference for the maintenance personnel to do preventive maintenance and avoid dangerous accidents.

The inspection of the external structure of the aircraft mainly includes:

1. Front fuselage: the appearance of the nose skin is not damaged; The radome shall be free of damage and lightning strike marks; The pitot tube, full temperature probe and angle of attack sensor are normal, and the skin around the pitot tube is free of damage and wrinkle; Visually check whether each antenna is intact and undamaged; There is no abnormal leakage in the discharge hole / outlet area;

2. Front landing gear and wheel well: there is no damage or leakage in the front landing gear and hatch area; The inner cylinder of the shock absorber strut is normally extended and clean; The safety fasteners of the connecting pin nut of the torsion arm are intact; The wheel rim and fixed screw are free of damage; Tire wear does not exceed the standard; There is no damage to the appearance of the taxilight of the front landing gear;

3. Right middle fuselage: the fuselage skin surface is not damaged; Check that the green release indicator of the oxygen system of the unit is intact; The right wing lighting, the right retractable landing light, the lower fuselage anti-collision light, the right wing landing light, the cornering light, and the emergency light have no damage on the surface; The communication and navigation antenna is not damaged; The static pressure hole is free of blockage and cover, and the Inner Mongolia skin within the RVSM sensitive area is free of damage and wrinkling;

4. Right engine and hanger: the T12 probe at the air inlet of the right engine is free of blockage and damage, and the latch is locked; The intake fairing, fairing cone, intake port, silencing plate, fan blade, wear layer, thrust reverser, exhaust tail nozzle, tail cone and visible turbine blade shall be free of damage; The oil filler cap of the oil tank should be covered well; The oil leakage of each remaining oil pipe and discharge pipe does not exceed the standard;

5. Right wing: navigation lights and strobe lights are clean without damage; Visually inspect the lower surface and tip of the wing from the ground to ensure there is no obvious damage and fuel leakage; The discharge brush is in good position; The fuel refueling panel is locked without damage;

5. Right main landing gear and wheel well: there is no damage or leakage in the right main landing gear and hatch area; The inner cylinder of the shock absorber strut is normally extended and clean; The safety fasteners of the connecting pin nut of the torsion arm are intact; The wheel rim and fixed screw are free of damage; Tire wear does not exceed the standard; The wear of the brake indicator pin does not exceed the standard (when setting the parking brake, the extension of the indicator pin should be ≥ 0.5mm after flight; when stopping for a short time, it should be ≥ 0mm);

6. Rear fuselage and rear operating rudder surface: the fuselage skin surface is not damaged; Visually check the visible parts of elevator, horizontal stabilizer, rudder and vertical tail from the ground to ensure there is no obvious damage and abnormal liquid leakage; The communication and navigation antenna is not damaged; The discharge brush shall be intact and in place; Whether the wear plate at the rear of the fuselage shows signs of rubbing the ground. If there is any sign of rubbing the ground, check whether the warning sign of the tail skid buffer assembly can see the green area. If the green area is not visible, replace the buffer;

8. APU area: APU inlet, APU cooling air inlet and exhaust port are free of damage and blockage, and APU residual oil port is free of leakage or oil leakage does not exceed the standard;

9. Left main landing gear and wheel well: refer to the standard of right main landing gear and wheel well;

10. Left wing: navigation lights and strobe lights are clean without damage; Visually inspect the lower surface and tip of the wing from the ground to ensure there is no obvious damage and fuel leakage; The discharge brush is in good position;

11. Left engine and hanger: refer to the standards of right engine and hanger;

12. Walk around inspection.